RHEINZINK – For the perfect circular economy

Minimising waste by reusing, repairing or recycling materials: This is the approach taken by the circular economy.

When it comes to raw materials, which are only available in limited quantities, it is especially important to extend the life cycle of products in order to meet demand. The climate and the environment also play a major role: Extracting new raw materials always involves CO₂ emissions. In this case, if we reduce the one thing, we reduce the other.

Building elements for roofs, façades and roof drainage made of RHEINZINK have a service life of over 100 years. RHEINZINK-brand titanium zinc used on buildings can be fully recycled and reused.

- 100% STABLE QUALITY

- SUSTAINABLE VALUABLE CYCLE

- ECONOMIC POTENTIAL

- SYSTEMATIC RECYCLING

- ECOLOGICAL ECONOMY

Thinking in cycles

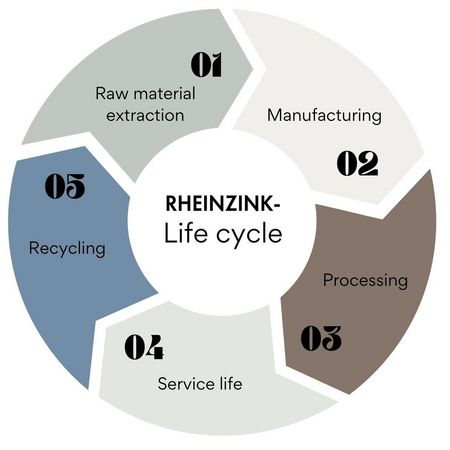

Thinking in cycles Let's imagine a construction world in which all materials, including waste materials, can be turned into a new product without any loss of quality. This is precisely the principle underlying the idea of a closed cycle. It encompasses the entire life cycle – from material extraction to reuse. Unlike conventional recycling, the aim is for a material to retain its original properties completely and be used for a new product of at least equal value (upcycling), rather than being reused in a lower-quality form (downcycling) or ultimately ending up in landfill. This technical and biological cycle prevents waste and reduces the burden on the environment in the long term.

How our material embodies the circular economy

1. Raw material extraction

The life of our material actually starts with the extraction of the raw materials. What is interesting here is zinc, as it makes up more than 98% of the material. Since it is traded on the stock exchange, we only have a certain influence on where it comes from. Nevertheless, most of our zinc – more than 90 per cent – comes from Europe. Especially from Sweden and Finland, and also from Belgium. Some of it also comes from Spain and Germany. It does not come from crisis areas, and that is something that is important to us.

Did you know? Zinc is not a supply-critical raw material in the sense of resource availability. Zinc resources will last for more than 700 years. At the same time, the amount of recycled zinc is constantly growing.

2. Manufacturing

Aspects such as environmentally friendly manufacturing processes and the use of renewable energies play a decisive role in our work. That is why we ask ourselves: Where does our energy come from and what makes our production particularly sustainable?

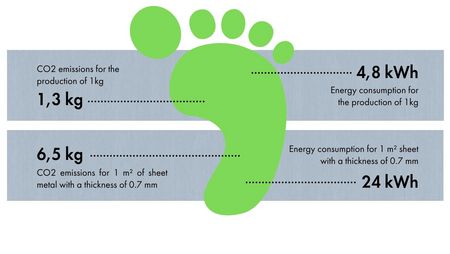

Our location is in the heart of the Ruhr region – a clear sign of ‘Made in Germany’. But origin alone does not make a building material sustainable. Our carbon footprint is crucial: due to its low melting point, comparatively little energy is required to produce zinc sheet. In addition, zinc is one of the lightest construction metals and causes the lowest CO₂ emissions during production. The high proportion of renewable energies in our electricity supply, which is already above the national average and will continue to rise in the future, makes an additional contribution.

3. Processing

As opposed to many other materials, when working with RHEINZINK, there are no health protection measures to be taken beyond the classic occupational health and safety measures. This speaks for the material's inherent naturalness. In addition, cuttings and RHEINZINK from conversion or renovation measures are collected by the processors and sold either directly or via the scrap metal trade to secondary smelters. There, the zinc scrap is sorted, melted, liquated and ultimately cast as zinc or zinc alloy.

4. Service Life

RHEINZINK sets standards with its service life of more than 100 years. The longevity of the material is based on the patina that develops over time - a matt grey protective layer that forms as a result of the natural weathering process. This provides the material with lasting protection. In addition, it ensures that RHEINZINK requires neither maintenance nor care during its long life.

Retrospective of the Lappersdorf Fire Brigade School

Functionality and beauty have merged for 45 years at the fire brigade school in Lappersdorf. In 1977, the Regensburg Land Building Authority decided on exposed brickwork and RHEINZINK roofing. This is still the visual focal point of the facility, which has already been extended twice, even after decades. The patinated grey roof surface made of RHEINZINK still provides a beautiful contrast to the red colour of the brickwork.

5. Recycling

Recycling typically describes a reuse process after which many materials no longer have their original quality and can subsequently only be used for less demanding purposes.

Compared to many other materials, the quality and product properties of the natural material RHEINZINK remain 100% intact during the recycling process. RHEINZINK is therefore a model material in terms of the CradletoCradle principle.

Examples of C2C-certified architecture

Eternally valuable: Prime example Kiasma Museum

Upcycling instead of downcycling is our motto. The Kiasma Museum demonstrates just how well this can be achieved with RHEINZINK. The famous museum in Finland's capital city of Helsinki is becoming a RHEINZINK material resource for new buildings being constructed in Sweden and Finland.

Kiasma, the Museum of Contemporary Art in Finland, was designed by Steven Holl and realized in the late 1990s. But due to a defective substructure, the museum is currently being renovated and will once again receive titanium zinc cladding. But the old, still intact material will also be reused.

With this project, the construction company wants to show how easy it can be to reuse materials, even on a large scale, and minimize the ecological footprint. Project manager Pär Johansson is convinced: "At the moment, the use of new materials is responsible for a large part of the climate impact. With this project, we hope to get a good picture of which materials have recycling potential." The project manager sees a great opportunity for construction projects and the environment in the zinc panels.

Partnership with Madaster

The circular economy is an issue that the company has identified as crucial. Since 2022, RHEINZINK has now been a Madaster Innovation Partner to enable property owners to realise circular buildings and promote the reuse of materials.

"Few materials can be recycled as effectively as titanium zinc. The continuous reuse without loss of quality is a major benefit in terms of climate neutrality and sustainability. As a material register, Madaster supports this recycling process by transparently presenting the product and its path from installation to deconstruction," says Dr Patrick Bergmann, Managing Director of Madaster Germany.

About Madaster

Madaster is a registry for materials that enables the circular use of products and materials in the construction industry. The online platform enables property owners and other stakeholders to store, manage, enrich and share data on their properties. In addition to creating material passports of buildings, Madaster enables financial and circular assessments that support the management and disposal of properties and the reuse of materials and products.

Durable and recyclable: That's RHEINZINK

You are on our global website.

Would you like to stay on rheinzink.com or visit the local RHEINZINK America website?