RHEINZINK horizontal panel

Benefits of RHEINZINK horizontal panels

- Modern, flat panel system for horizontal facade compositions

- Custom and perfectly matching production for any property

- Panel lengths up to 6000 mm possible

The horizontal panel with RHEINZINK

Panel systems are cost-effective facade design options and are popular among planners and builders alike. Builders and clients want clear structures and a design that is as subtle as possible, particularly in the private sector. The horizontal panel is ideal. It features clear lines whilst still incorporating the individual characteristics of the building. The clearly organised horizontal panel ensures that architects, planners and professional specialists have an excellent overview of the range at all times.

Our visualisation service can also be used in connection with horizontal panels to simplify the task of generating drafts and visualisations for your customers. We generate a photorealistic image based on a photo or draft. The distinguishing properties of our horizontal panels are described below.

RHEINZINK horizontal panel programme

Features of RHEINZINK horizontal panels

Horizontal panels are primarily distinguished by their clear design concept. However, different horizontal panels can be used to suit the respective project. In general, our horizontal panel system has the following performance characteristics:

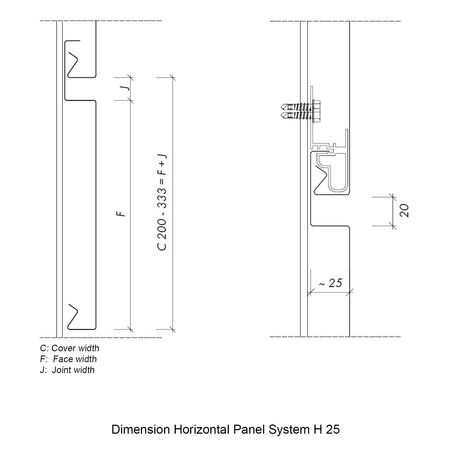

- The construction widths of individual horizontal panels are between 200 mm and 333 mm

- The individual panels are up to 6000 mm long allowing even large facade surfaces to be clad without any interruptions

- Shadow gaps 20 mm wide produce a clear structure and make a visual statement

- Even unusual facade surfaces, such as curves, can be clad using H 25 horizontal panels

- Assembly is simple yet thoroughly tried and tested. The individual panels are attached indirectly and invisibly

Indirect attachment using a rail specially developed for the system reduces stresses in the material caused by temperature-related changes in length. This enables panels of up to 6000 mm in length to be planned without the panel surface becoming excessively uneven.

Horizontal panel planning and application

System description

- Horizontal installation

- Assembled from bottom to top

- Indirect and concealed attachment

The horizontal panels have an installation depth of 25 mm and a fixed shadow gap of 20 mm, unlike our reveal panels. These dimensions are determined by the system's integral fastening rail. They can only be installed horizontally. Their advantage over other systems is that panels up to 6000 mm long can be produced. This gives you the greatest possible freedom when designing the facade layout.

Dimensions and metal thickness

- Construction width 200 mm - 333 mm

- Metal thicknesses 1.0 mm/1.2 mm (1.2 mm recommended for construction widths ≥ 250 mm)

- Standard lengths 3000 mm and 4000 mm

- Max. length 6000 mm

We generally recommend stiffening the ends of the panels using end plates. These are required to guarantee a perfect surface, particularly for larger construction widths from 250 mm upwards. The end plates also prevent side gaps in the panels e.g. around outside corner profiles.

The indirect attachment of the horizontal panels using the fastening rail allows temperature-related changes in length to be absorbed without causing tension.

The resulting vertical joints can be given different designs using, for instance, backing splice plates or pilaster strip profiles.

Customised forms

- Concave and convex rounded panels

- Face perforation

If necessary, our horizontal panels can be used to clad a variety of curved surfaces as well as flat surfaces. Our range is complemented by concave and convex rounded horizontal panels. The radii, construction widths and lengths are critical for the production and feasibility of rounded horizontal panels. Our team would be glad to answer your questions and to find out whether your ideas can be implemented.

Panel faces can be fully or partially perforated, either as a design element or for ventilation purposes, e.g. as ventilation or aeration elements below roof overhangs or for ventilated roof structures. RHEINZINK Service fabrication offers various perforation patterns for this purpose.

Attachment

As suppliers of tried-and-tested system solutions, we naturally provide more than just the required quantities of horizontal panels. Our programme also covers matching fastener solutions and further accessories. For instance, a special fastening rail that guarantees rapid installation is available for our horizontal panels.

RHEINZINK horizontal panels are attached by clipping them into the fastening rail. The fastening rail is attached to the metal substructure using two rivets or self-drilling screws. The required spacing of the substructure depends, amongst other things, on the wind load, the type of support structure, the structural system and the load bearing capacity of the cladding and requires appropriate structural analysis.

Technical information on RHEINZINK horizontal panels

The RHEINZINK team and our numerous trade partners are, of course, available at all times if you have any further questions. All important technical information concerning our horizontal panels and system components is available on our web page including examples of patterns and design suggestions.

Checklists, materials lists and specialist information considerably simplify the application of our solutions in day-to-day work. In this way, you can offer your customers swift facade design whilst you benefit from tried-and-tested materials and reliable technology. We look forward to hearing from you!

Downloads

You are on our global website.

Would you like to stay on rheinzink.com or visit the local RHEINZINK America website?