We support building of the future

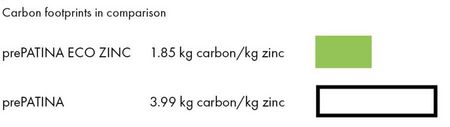

prePATINA becomes prePATINA ECO ZINC - with 50% less CO2 compared to the previous prePATINA product line

Mankind faces the task of drastically reducing CO2 emissions. The EU wants to become climate neutral by 2050. There is no doubt that the construction industry also has a great responsibility. That is why we have firmly integrated sustainability into our corporate strategy. With prePATINA ECO ZINC, we are taking another important step forward on the path of our sustainability strategy. Not through compensation, but in real terms with genuine renewable energies.

Titanium zinc is characterised by an exceptionally long service life of up to 100 years. This longevity contributes significantly to its environmental friendliness, as fewer resources are required for replacement or repair. Thanks to the natural formation of a protective patina, the material remains durable for decades without additional maintenance. These properties also apply to our prePATINA ECO ZINC product line. The long service life and durability of titanium zinc make it a sustainable choice for environmentally conscious construction projects.

prePATINA ECO ZINC in figures

CO2-reduced raw material thanks to renewable energies.

RHEINZINK is taking a big step towards decarbonisation in the procurement of raw materials. prePATINA, RHEINZINK's product line with the pre-weathered surface, is now prePATINA ECO ZINC. We use the low-carbon zinc of our long-term partner for this purpose. The raw material is produced in Scandinavia with renewable energy. Verifiable and certified.

Zinc – a future-proof material.

With a smaller CO2 footprint than the previous prePATINA product line and the proven advantages of titanium zinc – such as 100 % recyclability, exceptionally long service life and almost completely maintenance-free – prePATINA ECO ZINC is the ideal material for the future. The emission in the entire manufacturing process is only 1.85 kg CO2 per kg of zinc. The conversion will save us more than 36,000 tonnes of CO2 per year. By comparison, this is equivalent to the CO2 emissions of a small town with 4,500 inhabitants."

A large part of the carbon footprint of RHEINZINK products is generated in the supply chain, particularly during the extraction of raw materials. We source our raw material zinc for the ECO ZINC product line from a Scandinavian supplier that mines and processes zinc using renewable energy. This means that zinc can be produced and supplied in a CO₂-reduced manner. The amount of CO₂ saved is allocated to the products in the ECO ZINC line via mass balancing.

Pre-weathered ex works.

The pre-weathering process creates the uniform blue-grey appearance of the zinc patina ex works and allows the natural patina process of prePATINA ECO ZINC to take place afterwards. The highlight: during the staining process, the natural surface properties are retained and the surface can still be soldered. For almost infinite longevity of the building material.

prePATINA ECO ZINC is available in the surface colours blue-grey and graphite-grey.

Discover the world of fascinating prePATINA ECO ZINC surfaces and request your product samples now.

Self-healing and low-to-no-maintenance.

prePATINA supports the sustainable building in the future thanks to its long service life and low-to-no-maintenance properties. Another trump card is the self-healing effect of the high-quality material. Installation-related scratches are evened out again as part of the natural patina formation. With its effective accents, the prePATINA-Line is the perfect surface for a unique building.

Sustainability and RHEINZINK – an exciting relationship.

CO2 savings in comparison to the previous prePATINA product line.

Test station on Helgoland

For over 10 years, we have been using the offshore climate on Heligoland to test our surfaces under extreme weather conditions. We document the behaviour of the surfaces at regular intervals. The test results are analysed in the Research & Development department at RHEINZINK. In this way, we constantly check how our surfaces react to challenging site-specific climatic conditions, even in the long term, and derive possible optimisations from this.

You are on our global website.

Would you like to stay on rheinzink.com or visit the local RHEINZINK America website?